South Africa's managing director and chairperson of German car manufacturer Volkswagen said it had not been spared the effects of load shedding and was forced to rent generators which, over two years, had cost R130 million to rent and supply fuel for.

This is money that could have been used for corporate social investment or expanding its operations.

“If our other plants in the world can present a better business plan for the provision of vehicles for the rest of the world then it is a problem for Volkswagen South Africa,” Martina Biene of VWSA has said.

The brand's local affiliate was established in 1946 and is the largest German investment in the country as well as a major contributor to foreign direct investment, technology transfer and skills development.

“All the original equipment manufacturers in the Eastern Cape, ourselves, Isuzu and Ford are affected by the situation, as well as the collapse of the rail system,” she told 702.

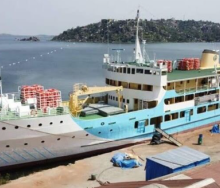

She praised Gqeberha for managing to provide it with a good port service for its exports and imports.

At present its exports are strong, but imports are a problem as the rand is weak.

She added that accessing Gauteng was also a problem as they were forced to transport new vehicles to the province by road – Gauteng is the most important local market.

One train is replaced by up to 200 transport vehicles, which is an additional expense and has its own negative carbon emission issues.

Biene highlighted that the road option was also hampered by the state of the country’s roads when moving vehicles from its Uitenhage assembly plant.

“We have had a production presence in South Africa for decades and want to remain.

"We are still treating it as our gateway to the African market,” she said.